SOLARFLEX

home > our-technologies > solarflex

SolarFlex Fruit and Vegetable Dryer

Malnutrition Matters, in partnership with SolarFlex Inc., has developed an innovative solar fruit and vegetable dryer that has a flexible design and is inexpensive to manufacture. Drying fruits and vegetables with this system is a cost-effective long-term food storage solution that requires no external electricity to operate, and eliminates the need for chemical preservatives. The fruit dryer is powered entirely by the sun and requires minimal operator skill. The ability to dry fruits and vegetables is a crucial element in achieving the long-term food security of many communities, where certain crops may be abundant during harvesting season, the lack or high cost of canning and refrigeration facilities makes these foods unavailable at other times.

According to Donald Mercer, PhD Food Technologist and published expert on food drying, “Based upon personal experience in a number of countries in Sub-Saharan Africa and Central America, I believe that the Solar-Flex Dryers offer a well-designed alternative to many of the solar dryers currently in use. The manner in which they function is extremely impressive. The design features incorporated into the Solar-Flex dryers have made it easy to use with a minimum amount of formal training and instruction.”

Fr. S.J. Mathew, MD and founder of Solar Alternatives, an NGO in India with experience in solar drying reported: “the solar dryer which I got from you was quite useful for quality solar drying. We fixed four wheels on the four corners of the dryer for tracking the entire dryer which again increased the efficiency of the system. We could dry all the seasonal fruits and vegetables in that, like mango, banana, supporta, gooseberry etc. We could get good color and clean dried products."

This solar dryer is intended for the small landholder or a family. With a capacity of 10 - 20 kg of sliced wet fruit or vegetables, depending on type of fruit and numerous other factors, this dryer is ideal for high-quality natural preservation in a micro-enterprise setting. At a unit cost between $1,650 and $1,900 (depending on size of order), multiple units provide a significant commercial production volume at a cost which remains economical and substantially lower than large commercial solar dryers.

"Small Farm" Dryer ("Quad" Dryer for commercial use, below)

This model has three main features that will enhance drying speed and efficiency. This compact configuration provides for:

- Horizontal airflow across the food is proven superior versus vertical airflow.

- Solar air collector tilts to accommodate any latitude or season.

- Entire dryer can swivel on a fixed table so operator can rotate unit to track the sun.

Loading side of the cabinet showing aluminum trays.

SolarFlex Small Farm food dryer with collector set at 0 degrees.

Fruits being cut and loaded onto trays in St. Lucia.

Fruits after drying.

Pineapple being loaded for drying in Liberia.

Small Farm Dryer at SOFDI, in Kenya - 2016 (Sponsored by A Better World AG)

As part of their School Outreach Program they are drying African Leafy Vegetables (ALVs) that include Amaranth, Black Night Shade, Crotolaria, Jute Mallow, Spider Planter. These are the vegetables whose supply is very low during the dry season, but they are high in micro-nutrients, have medicinal benefits and are resistant to pests and diseases.

FAO Demonstration and Training Systems | St. Lucia, Carribbean, March 2011

Under the terms of an agreement between FAO and Malnutrition Matters, for the provision of SolarFlex food dryers, two different models were installed in March by MM tech specialist Charles Lauzon. At Fond Assau, both the traditional vertical style and the newly designed horizontal SolarFlex “Small Farm” dryer were installed and operated with a team designated by the St. Lucia Ministry of Agriculture. The terms of the agreement call for additional trials and data collection over at least 8 weeks. This will establish tropical performance information for various kinds of fruits, vegetables and herbs and also compare the vertical and horizontal data.

SolarFlex horizontal “Small Farm” prototype model. Tilting solar air collector can angle to any solar angle and latitude. The whole system can rotate on the table to face the sun throughout the day.

Dryer being loaded with sliced pineapple. 8 racks with stainless steel mesh can be loaded with up to 20 kg of wet fruit depending on type of fruit, thickness of slice etc. Normal target is same day drying but this depends on the length of the sunshine / day and other variables such as ambient humidity, type of food etc.

Dried pineapple and “sourey” sour fruit, ready to package and store for many months in simple plastic bags. These are highly valued, healthy snacks and help provide food security for seasons where some fresh products are not available.

Quad Series

Expandable Commercial Dryers

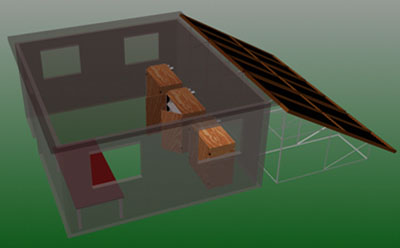

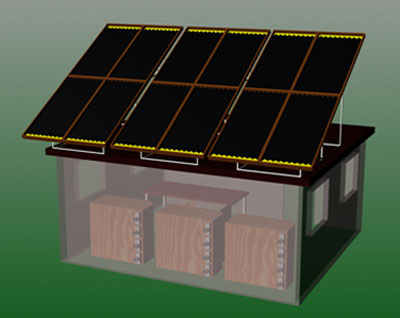

This economical line of commercial dryers is conveniently expandable by simply adding modules of the Quad solar air collectors and the respective drying rack capacity. This series also allows the choice of rooftop installation of the solar air collectors to feed hot air directly down into a suitable small building where the drying racks are installed in any capacity. Alternatively these collectors can be mounted on the ground directly beside the wall of the small building housing the drying racks.

Each group of four solar air collectors is matched to 2 fans, ductwork and a cabinet of 24 drying racks, so that approximately 50 - 60 KG of wet fruit can be dried at one time. By simply adding modules this can be multiplied depending on the capacity required.

The intent is to allow projects to build their own cabinets inside their building or in a dedicated shed, while the critical components are supplied, including: Solar air collectors and stands, fans, ductwork, controls, and optionally the aluminum racks.

A typical cabinet is shown here with a 24 rack capacity, matched to the single Quad solar air collector. For single installations, the cabinet can be placed directly under the air collectors. For larger projects it is recommended that a small building house the drying racks and cabinets.

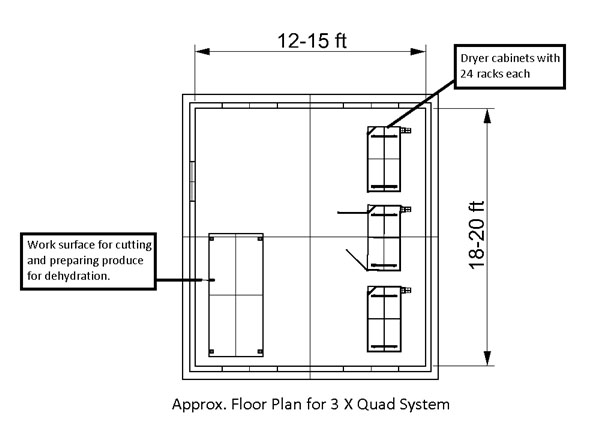

Example: For a project with a 3 x Quad series capacity, a building of about 10 sq. meters is enough to house the drying cabinets with a capacity of 72 racks and about 150 – 200 kg “wet” food drying capacity.

A sturdy building with a flat roof, would allow the three quad group to be roof-mounted to take advantage of the downwards hot airflow coming out of the manifold at the bottom of the solar air collectors.

This SolarFlex Quad system, like the “Small Farm” model, employs the high-performance horizontal airflow method through the cabinets and drying racks. This method, though slightly more complex, has been scientifically proven to be superior to typical vertical airflow systems. Horizontal airflow allows the drying air to sweep across the surface of the food (including the “boundary layer”) which is much more efficient than pushing up air against the bottom of the food.

To maximize airflow efficiency, the Quad series draws air downwards through the collectors to allow the hot air outlet ducts to be directed into the cabinets and the building either from the rooftop installation or from the ground. The photo shows the manifold, ducts, and fans coming off the Quad collectors, and the control panel.

Above is a typical installation of three Quad collectors on the ground of the building.

Above is a typical installation of three Quad collectors on the roof of the same building.

The above sketch shows the approximate size of the small building and interior space required for three Quad series collectors and their respective cabinets in the building.

Projects requiring specific configurations of 3 or more Quad dryer combinations will be provided with drawings and material specifications to allow them to prepare their own building, including drying cabinets. Turnkey packages including solar air collectors, fans, controls stands and ductwork can be supplied. Approximate price is $5,900. per complete Quad unit including cabinet and racks.

VitaGoat | SolarFlex | SoyaKit | Heat Pump Dryers | SoyCow

Stay Up to Date

Questions?

Request more information from matters@malnutrition.org

© 2020 Malnutrition.org | Malnutrition Matters. All Rights Reserved.